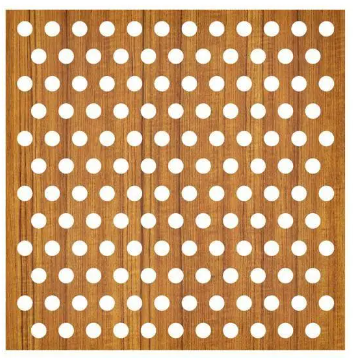

zebra-stripe Flame Retardant Grooved Wooden Acoustic Panel

Send InquireProduct Details

zebra-stripe Flame Retardant Grooved Wooden Acoustic Panel

- Product Model: 28/4

- Product Base Material: Three Layers Composite Flame Retardant Basic Material

- Product Finish: Melamine

- Product Size: 2440*133 / 197*15 mm

- Product Thickness: 12 mm 15 mm 18 mm

- Environment Protection Grade: E1

Product Description

The Three Layers Composite Flame Retardant Grooved Wooden Acoustic Panel is made of high-quality MDF board. According to the customer’s acoustic and decoration requirement, our Three Layers Composite Flame Retardant Grooved Wooden Acoustic Panel can equipped with outstanding environmental, flame retardant and waterproof function with various colors and finish choices.

- Type for choose:

- surface 1 groove: 59/5 60/4

- surface 2 groove: 40/3 38.5/4

- surface 3 groove: 28/4 29/3

- surface 5 groove: 18/3 17/4

- surface 7 groove: 13/3 14/2

- Finish:

- Melamine, natural wooden veneer, fireproof board, painting, metal, technology veneer, leather etc.

- Highest Fire proof Grade

- Meet the request of the test basis GB 8624-2012 “Combustion performance classification of building materials and products” A Grade (A2-s1, d0).

- Highest Eco Grade

- Meet the request of the test basis GB 18580-2001 ”Formaldehyde emission limits in interior decoration materials, wood-based panels and their products” E1 Grade.

Application : Suitable for opera, theater, studio, recording studio, television studio, radio station, business hall, multi-function hall, conference room, banquet hall, auditorium, gymnasium。Project Case

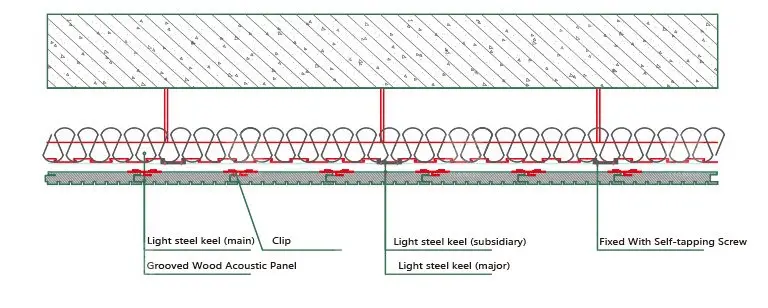

- First fix the aluminum profile onto the wooden frame or bottom board, and their distance suggested about 600 mm.

- Filled the 32-64 kg/m density acoustic foam among aluminum profiles.

- Use the clips to fix the perforated acoustic panel to the aluminum profile.

- When install several acoustic panel, the distance between noses to noses suggested 2-3 mm.

- If install the acoustic panel in the horizontal way, then the notch of the panel should face down, and it need to be fixed tight with clips. After that install pieces and pieces of acoustic panel onto the lowest one.

Color Seletction

Send Inquire