White Sound Barrier PVC Sound Deadening Pad MLV

Send InquireProduct Details

This Sound Barrier/MLV is our attempt to dispel any fiction about Mass Loaded Vinyl (MLV) and give you the facts in a FAQ format.

Mass Loaded Vinyl is the material of choice for use as a sound barrier. Mass Loaded Vinyl, commonly known as MLV, is a heavy, PVC vinyl sheeting material that is used to stop sound transmission. The weight of MLV is the product of infusing the PVC vinyl sheet with a calcium carbonate, which gives MLV its density while retaining flexibility. MLV has been used for soundproofing purposes dating back to the 1960s and is still considered to be one of the most effective sound-blocking materials on the market. NEW white Mass Loaded Vinyl is a safe, non-toxic, odorless barrier designed to hang as a limp mass in a variety of soundproofing applications.

All Mass Loaded Vinyl is measured by weight, specifically, pounds per square meter. This correlates to the thickness of the material, but since MLV is produced to a precise weight per square meter, there might be slight variances in the thickness..

Outside of how much they weigh, or the size, different weights of MLV have different degrees of sound blocking capabilities. These are measured with different STC ratings, which you can read more about here. The simplest way to think about it is this: The heavier the material, the better the soundproofing quality.

| Product Name | White Sound Barrier PVC Sound Deadening Pad MLV | |||||

| Thickness | 1.2mm or 2mm or 3mm or 6mm | |||||

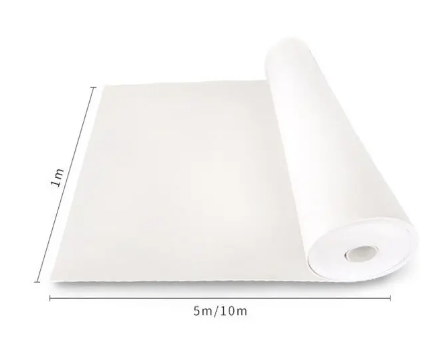

| Size | 1000mm*5000mm*3mm or 1000*10000*2mm/1.2mm | |||||

| Color | Pure White | |||||

| Type | Reinforced | |||||

| Weight | 2.1kg/sqm for 1.2mm and 5.6kg/sqm for 3mm and 3.7kg/m2 for 2mm | |||||

| Tensile Strength | 400 p.s.i. request | |||||

| Tear Strength | 12.9 kg/cm (72 lb/in) | |||||

| Ultimate Elongation | 40% (min.) | |||||

| Temperature Range | /-40 deg. F to 180 deg. F | |||||

| Flammability | B Grade | |||||

What is MLV?-Sound Barrier/MLV-FAQs

Mass loaded vinyl (or MLV) is an acoustical barrier that blocks sound wave transmission to provide excellent noise reduction. Safer than lead and denser than drywall,mass loaded vinyl is a high density, limp material that’s engineered to be an effective sound barrier. Manufactured from Pure White PVC vinyl that has been compounded with inert materials to increase density, MLV is well suited for automotive, industrial, and building applications.

Mass loaded vinyl is typically colored black with a density between 3kg to 6kg per square meter. It’s most often bought in large rolls, but Second Skin also sells sheets because they’re much easier to ship and some projects need less square footage.MLV is odorless, heat resistant, waterproof, tear resistant, and has a high STC rating for effective noise blocking. One of the most common uses for MLV is soundproofing walls.

Because mass loaded vinyl is flexible, it’s the ideal noise blocking material to fit around the contours of a vehicle. It’s extremely effective for home or commercial use as well, and often used to reduce noise transmission in in soundproofing ceilings, floors, walls, machinery enclosures, ductwork, a generator sound box, to soundproof a door, and even to build a DIY sound barrier fence. Because it’s so heavy, MLV should be adhered with an extremely strong adhesive (like acrylic tape or vinyl cement) or fastened with screws, staples, nails, or reinforced grommets.

How does MLV work? -Sound Barrier/MLV-FAQs

Transmission Sound Barrier/MLV-FAQs Figure 1

In order to understand how MLV attenuates sound, we need to first make an analogy with the field of mechanical vibrations. As shown in Figure 1, let us assume that an acoustic wave can be represented by a single degree of freedom oscillator, with a single peak of high amplitude (shown in red). MLV essentially acts like a tuned mass damper, that is capable of reducing the magnitude of the single peak into two peaks (shown in magenta), where the lower peak is the vibration mode of the coupled system, and the higher peak is the vibration mode of the MLV sheet. This curve would be representative of an MLV sheet that has no damping (or viscoelasticity). MLV with a greater degree of viscoelasticity will be seen as providing greater damping, as shown in the green peaks. At an optimal amount of damping, the vibration response would be represented by the blue curve, which has a magnitude of about 14, and is more than four times lower than the original red peak. This is the primary mechanism by which MLV works. In actuality, a sheet of MLV will have several vibration modes that occur over a wide frequency range.

Is a thicker MLV sheet better than a thinner sheet?-Sound Barrier/MLV-FAQs

A one-eighth inch thickness of MLV will have a weight density of one pound per square foot, and a one-quarter inch thickness will have a density of two pounds per square foot. Generally, the greater the mass and thickness, the better the low frequency attenuation capability of the MLV sheet. This is due to the fact that the thicker material will provide a greater impedance mismatch than a thinner material, which will tend to extinguish an acoustical wave that tries to pass through the material. However, going back to our vibration analogy, it is important to note that it is the ratio of stiffness to mass that determines the effectiveness of the MLV to attenuate noise. Therefore, a stiff MLV sheet with higher density may not be as effective as a compliant MLV sheet with a lower density. The user must therefore examine the compliance of a thicker sheet to ensure that it will work better than a thinner sheet at the frequency range of interest.

Can I bond MLV directly to a wall or partition?-Sound Barrier/MLV-FAQs

There are many manufacturers of “peel-and-stick” MLV, which has a layer of adhesive on one side to facilitate attachment of the sheet to a structure. Some users may want to reduce noise attenuation through a wall by bonding MLV directly to a wall using construction or carpet adhesive. Bonding the MLV to a wall or partition defeats the purpose of MLV, and will result in only a modest amount of sound attenuation.

Going back once again to our vibration analogy, it is our desire to allow the MLV to vibrate independently as it will attenuate acoustical energy in two ways: (1) the acoustic waves encounter different impedance interfaces by having to propagate from the air, through the MLV, through the air, then through the wall or partition, and (2) the acoustical energy is dissipated by the tuned mass damper effect of the MLV sheet. By bonding the MLV directly to the structure, the MLV sheet cannot act independently of the structure and therefore cannot attenuate acoustical modes. We therefore do not advise that MLV be stuck directly to a wall or partition

We usually can use Acopanel PET acoustic panel to install on the surface of MLV.Sound absorption and sound insulation will achieve the best effect

Should I mount the MLV vertically or horizontally within a wall or partition? -Sound Barrier/MLV-FAQs

Generally, the orientation of the MLV when hung on a wall or partition should not matter. However, the MLV should be hung in a manner that will minimize the amount or number of seams. Seams in the MLV will comprise sound transmission flanking paths that need to be blocked using acoustical caulking or tape. Therefore, when soundproofing a wall in a house (for example), it will be more effective hanging the MLV sheet horizontally, leaving a single continuous horizontal seam that can be more readily treated with caulking or tape.

Send Inquire